Tooling

By leveraging our extensive experience and technical proficiency, we provide our clients with the assurance that their investments in tooling will yield maximum returns, with minimized risks of downtime or inefficiencies.

With Seongju as their trusted partner, businesses can confidently navigate the complexities of tooling management, knowing that their time and financial resources are optimized for success at every stage of the process.

Decades of Tool Building

Precise Tooling = Precise Products

Recognizing the substantial investments of time, capital, and effort associated with tool development, it becomes imperative to strive for accuracy and efficiency from the outset.

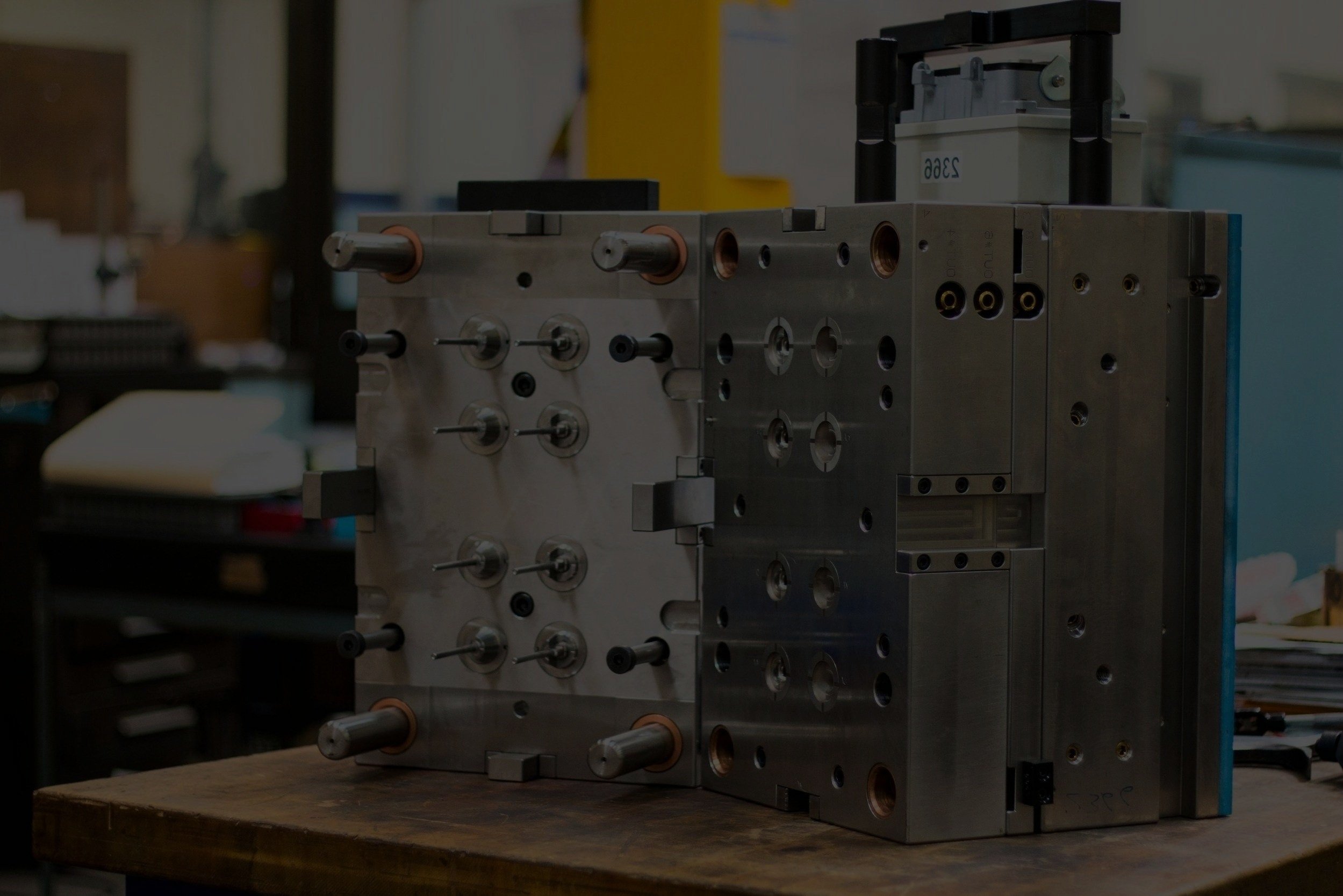

As a turn-key manufacturer, Seongju remains acutely attuned to the pivotal role of seamless tool design and development in meeting client expectations. To this end, we harness comprehensive in-house capabilities for tool construction.

Our in-house approach enables us to offer our clients an effortless and streamlined experience, ensuring that their tooling needs are met with precision and professionalism, regardless of complexity or scale, mirroring our commitment to delivering unparalleled value and excellence at every stage of the manufacturing journey.

Minimizing Lead Time

The intricate process of tool development demands meticulous attention to detail and substantial investments of time and resources. Similarly, the upkeep and maintenance of these tools during their operational lifespan require a proactive and dedicated approach to ensure optimal performance and longevity.

At Seongju, we recognize the critical importance of both phases in the tooling lifecycle and have cultivated a robust network of skilled tool builders alongside a comprehensive in-house development capability. Through this integrated approach, our customers benefit from a seamless continuum of service, where the expertise and resources necessary for tool development seamlessly transition into ongoing maintenance and support.

In-house Capability

An in-house tool development capability offers a multitude of advantages for businesses, including streamlined processes and enhanced efficiency.

By maintaining this capability internally, Seongju can significantly reduce lead times during the development phase, allowing for faster turnaround times and accelerated project timelines.

Furthermore, having dedicated resources for maintenance and servicing ensures the ongoing reliability and performance of tools, minimizing the risk of unexpected downtime and associated disruptions to production schedules.

Immediate access to in-house expertise also facilitates prompt troubleshooting and resolution of issues, further reducing downtime and optimizing operational continuity.

Aspects of Tool Making

Built to Last

Crafting a tool entails meticulous consideration of numerous factors tailored to meet the precise specifications of each project. From selecting the optimal core metal and determining the appropriate number of cavities to customizing the base and beyond, every aspect is meticulously fine-tuned to ensure seamless integration within the production process.

Recognized as a lasting investment for organizations, the development of a tool serves as the cornerstone of smooth and efficient production throughout a project's lifecycle. At Seongju, we approach this task with the utmost gravity and dedication, leveraging our decades of expertise to deliver tooling solutions that not only meet but exceed the expectations of our clients. With an unwavering commitment to precision, quality, and reliability, we stand as your trusted partner in navigating the complexities of tool development, ensuring optimal outcomes and enduring success.